Photo: Jentschmann

Photo: Jentschmann

Photo: Jentschmann

The variance of piping types and the manufacturers’ philosophies regarding which piping should be used on which awning are manifold. But there is one thing that all textile hangings have in common, such as awnings etc.: There is a sewn fabric fold-over on the front profile and in most cases on the fabric shaft. With its NonVi piping, Jentschmann AG from Hüntwangen near the German border has created an innovation in which precisely this fabric fold-over is eliminated, making significant improvements possible in the area of the front profile and the fabric shaft.

A completely new approach

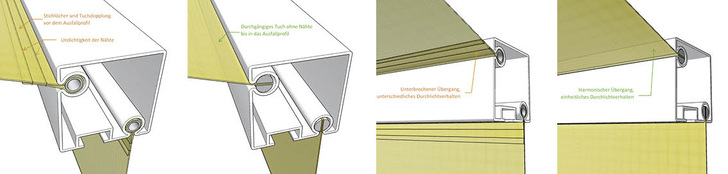

Soft piping, hard piping, magnetic claw piping or quick assembly piping. Many roads lead to Rome here with a wide variety of results. All piping shares two problems: thickenings on the fabric shaft, which does not have a positive influence on the winding behaviour, and a sewn fabric fold-over on the front profile, which can cause leaks and represents a visual problem in vertical awnings. Dietmar Heil, the owner of Jentschmann AG, has thought about this with his team, and developed a technical innovation with the NonVi (non visible) piping. For this purpose, tabless piping is force-fitted to the fabric and not inserted loosely into a hemstitch as is common today. This piping usually consists of a two-part profile that can be made of either soft or hard materials up to a diameter of 8 mm.

New coverings made easy

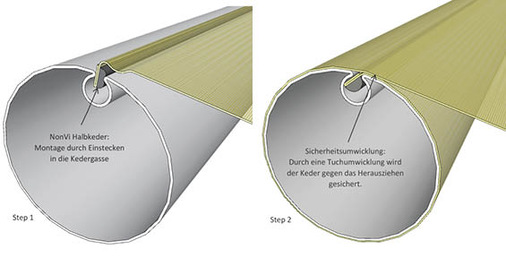

Alternatively, a half piping profile can be used, provided that the safety wrap on the shaft is ensured. The fabric is folded over at the edge and the piping half/halves is/are sewn onto the folded-over edge of the fabric. The now friction-locked piping connection disappears completely in the piping groove of the fabric shaft and/or in the front profile. This offers great advantages, especially in the area of new coverings, when the piping has to be pulled in from the front over the shaft. The lack of a seam fold-over offers great advantages, especially in the area of seam doubling through the connection of the awning fabric webs, because here only two layers of fabric have to be pulled through the piping strip instead of the usual four layers of fabric.

Technical and optical advantages

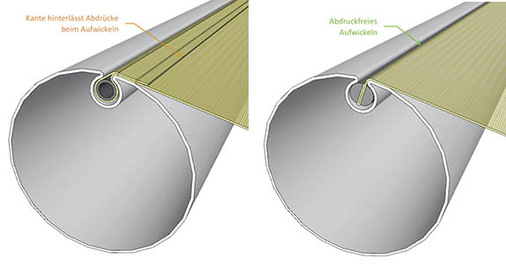

Due to there no longer being any seam on the front profile, the entire fabric is guaranteed to be water-tight (glued in case of longitudinal seams). Uniform transmitted light behaviour (no visible seam) improves the look. When using the NonVi piping on the fabric shaft, there are no changing layer thicknesses. This ensures better winding behaviour and eliminates the imprints that are unavoidable today due to the layer jumps on the shaft. If a hard material piping is used, this has the advantage that a fixation can be produced in the front profile. By precisely cutting the hard material piping to length, the piping is prevented from wandering between the end caps in the front profile for both the articulated arm awning and the vertical awning. Soft materials can be stretched as required and fixed accordingly in the piping lane. The result in both cases is a significant reduction in wrinkling in this area.

Nomination for the Innovation Award

The European patent application for the NonVi piping was filed on 20.02.2019, thus also creating the conditions for registration with the R+T Innovation Award. The USPs of the product, such as the uniform transmitted light behaviour (no visible seam), the waterproofness over the entire fabric (elimination of the seam perforation in the visible area) and the long-term shape stability (better winding behaviour), were convincing points in the preliminary judging to be nominated for the Innovation Award.